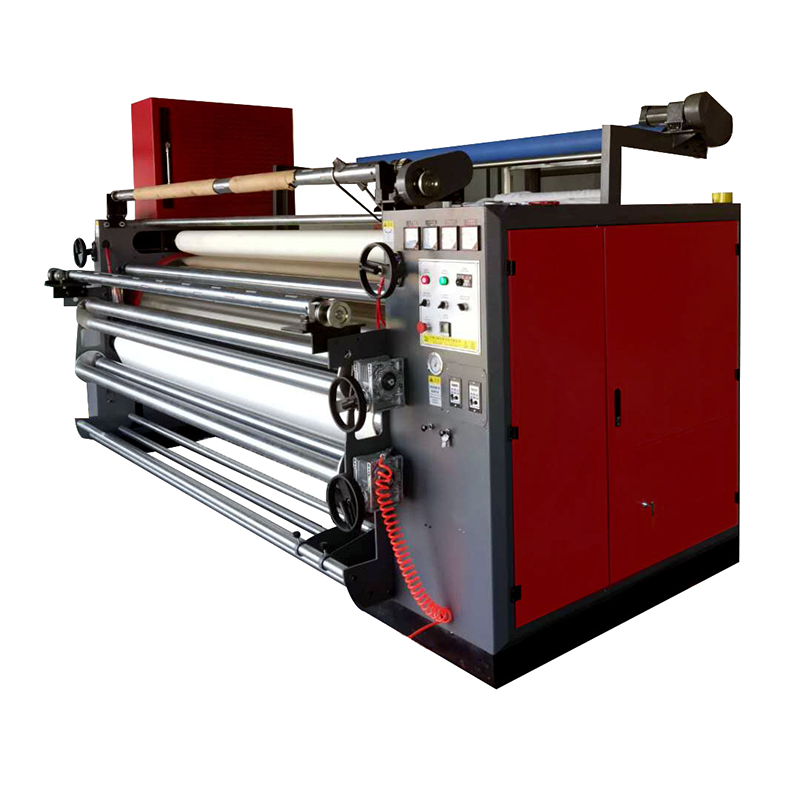

Sublimation Textile

Sublimation textile printing is commonly used in the production of custom sportswear, flags, banners, and other textile-based products. This method is preferred for its ability to produce high-quality prints with excellent color accuracy and detail.